Page 234 - DME Workshop Equipment Catalogue 2023 EN

P. 234

LIFTING EQUIPMENT

WORKSHOP EQUIPMENT - LIFTING EQUIPMENT

LIFTING POINTS WITH RFID

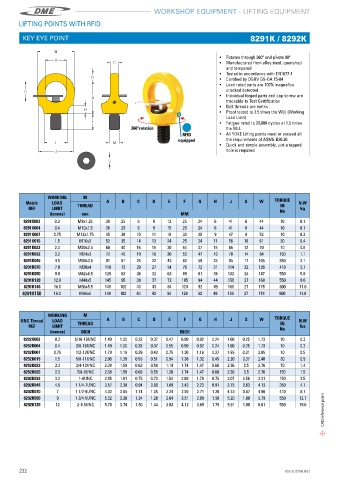

KEY EYE POINT 8291K / 8292K

• Rotates through 360º and pivots 90º

• Manufactured from alloy steel, quenched

and tempered

• Tested in accordance with EN1677-1

• Certified by DGUV GS-OA 15-04

• Load rated parts are 100% magnaflux

cracked detected

• Individual forged parts and cap screw are

traceable to Test Certification

• Bolt threads are metric

• Proof tested to 2�5 times the WLL (Working

Load Limit)

• Fatigue rated to 20,000 cycles at 1�5 times

360°rotation the WLL

RFID • All YOKE Lifting points meet or exceed all

equipped the requirements of ASME B30�26

• Quick and simple assembly, just a tapped

hole is required

WORKING M

Metric LOAD A B C D E F G H J S W TORQUE N.W

IN

REF LIMIT THREAD Nn kg

(tonnes) mm MM

8291K003 0�3 M8x1�25 38 25 9 9 12 25 24 6 41 6 44 10 0�1

8291K004 0�4 M10x1�5 38 25 9 9 15 25 24 6 41 6 44 10 0�1

8291K007 0�75 M12x1�75 45 30 10 11 18 33 30 9 47 8 52 10 0�2

8291K015 1�5 M16x2 52 35 14 13 24 25 34 11 56 10 61 30 0�4

8291K023 2�3 M20x2�5 60 40 16 15 30 44 37 15 65 12 70 70 0�6

8291K032 3�2 M24x3 72 49 19 18 36 53 47 19 78 14 84 150 1�1

8291K045 4�5 M30x3�5 91 61 24 22 45 62 59 23 95 17 105 350 2�1

8291K070 7�0 M36x4 110 73 29 27 54 76 72 31 114 22 126 410 3�7

8291K090 9�0 M42x4�5 128 83 34 32 63 89 81 38 132 24 147 550 5�8

8291K120 12�0 M48x5 145 95 38 37 72 105 94 44 150 27 168 550 8�6

8291K140 16�0 M56x5�5 148 102 40 43 84 124 92 49 166 27 178 800 11�0

8291K150 18�0 M64x6 148 102 40 43 96 124 92 49 166 27 178 800 11�8

WORKING M

UNC Thread LOAD THREAD A B C D E F G H J S W TORQUE N.W

IN

REF LIMIT Nn lbs

(tonnes) INCH INCH

8292K003 0�3 5/16-18UNC 1�49 1�00 0�33 0�37 0�47 0�99 0�92 0�24 1�60 0�25 1�73 10 0�3

8292K004 0�4 3/8-16UNC 1�49 1�00 0�33 0�37 0�55 0�99 0�92 0�24 1�60 0�25 1�73 10 0�3

8292K007 0�75 1/2-13UNC 1�79 1�19 0�39 0�43 0�75 1�30 1�16 0�37 1�85 0�31 2�05 10 0�5

8292K015 1�5 5/8-11UNC 2�06 1�39 0�55 0�51 0�94 1�38 1�32 0�45 2�20 0�37 2�40 30 0�9

8292K023 2�3 3/4-10UNC 2�38 1�59 0�63 0�58 1�14 1�74 1�47 0�60 2�56 0�5 2�76 70 1�4

8292K025 2�3 7/8-9UNC 2�38 1�59 0�63 0�58 1�30 1�74 1�47 0�60 2�56 0�5 2�76 150 1�5

8292K032 3�2 1-8UNC 2�85 1�91 0�75 0�70 1�52 2�08 1�79 0�75 3�07 0�56 3�31 150 2�5

8292K045 4�5 1 1/4-7UNC 3�57 2�38 0�94 0�88 1�89 2�43 2�23 0�91 3�75 0�63 4�13 350 4�7

8292K070 7 1 1/2-6UNC 4�32 2�85 1�14 1�05 2�24 2�99 2�71 1�20 4�49 0�87 4�96 410 8�7

CAD reference point

8292K090 9 1 3/4-5UNC 5�02 3�26 1�34 1�26 2�64 3�51 3�09 1�50 5�20 1�00 5�79 550 12�7

8292K120 12 2-4�5UNC 5�70 3�74 1�50 1�44 3�03 4�12 3�69 1�75 5�91 1�00 6�61 550 19�6

232 store.dme.net