Page 55 - DME Workshop Equipment Catalogue 2023 EN

P. 55

MOULD MAINTENANCE EQUIPMENT

WORKSHOP EQUIPMENT - MOULD MAINTENANCE EQUIPMENT

WELDING MATERIAL

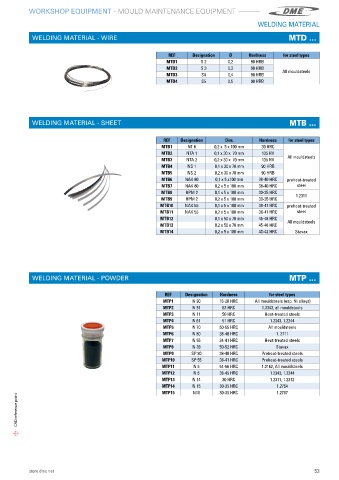

WELDING MATERIAL - WIRE MTD ...

REF Designation Ø Hardness for steel types

MTD1 S 2 0,2 90 HRB

MTD2 S 3 0,3 90 HRB All mouldsteels

MTD3 S4 0,4 90 HRB

MTD4 S5 0,5 90 HRB

WELDING MATERIAL - SHEET MTB ...

REF Designation Dim. Hardness for steel types

MTB1 NT 6 0,2 x 5 x 100 mm 30 HRC

MTB2 NTA 1 0,1 x 30 x 70 mm 135 HV

MTB3 NTA 2 0,2 x 30 x 70 mm 135 HV All mouldsteels

MTB4 NS 1 0,1 x 30 x 70 mm 90 HRB

MTB5 NS 2 0,2 x 30 x 70 mm 90 HRB

MTB6 NAK 80 0,1 x 5 x100 mm 38-40 HRC preheat-treated

MTB7 NAK 80 0,2 x 5 x 100 mm 38-40 HRC steel

MTB8 HPM 2 0,1 x 5 x 100 mm 30-35 HRC 1�2311

MTB9 HPM 2 0,2 x 5 x 100 mm 30-35 HRC

MTB10 NAK 55 0,1 x 5 x 100 mm 38-41 HRC preheat-treated

MTB11 NAK 55 0,2 x 5 x 100 mm 38-41 HRC steel

MTB12 0,1 x 50 x 70 mm 45-48 HRC All mouldsteels

MTB13 0,2 x 50 x 70 mm 45-48 HRC

MTB14 0,2 x 5 x 100 mm 40-42 HRC Stavax

WELDING MATERIAL - POWDER MTP ...

REF Designation Hardness for steel types

MTP1 N 90 16-20 HRC All mouldsteels (esp� Ni alloys)

MTP2 N 51 63 HRC 1�3343, all mouldsteels

MTP3 N 11 50 HRC Heat-treated steels

MTP4 N 61 51 HRC 1�2343, 1�2344

MTP5 N 70 50-55 HRC All mouldsteels

MTP6 N 80 38-40 HRC 1� 2711

MTP7 N 55 34-41 HRC Heat-treated steels

MTP8 N 39 50-52 HRC Stavax

MTP9 SP 80 38-40 HRC Preheat-treated steels

MTP10 SP 55 38-41 HRC Preheat-treated steels

MTP11 N 5 54-56 HRC 1�2162, All mouldsteels

MTP12 N 6 38-45 HRC 1�2343, 1�2344

MTP13 N 14 30 HRC 1�2311, 1�2312

MTP14 N 15 30-35 HRC 1�2764

MTP15 N16 30-35 HRC 1�2767

CAD reference point

store.dme.net 53