Page 250 - DME Workshop Equipment Catalogue 2023 EN

P. 250

WORKSHOP EQUIPMENT - CLAMPING EQUIPMENT

CLAMPING EQUIPMENT

BAKRA CLAMPING SYSTEM

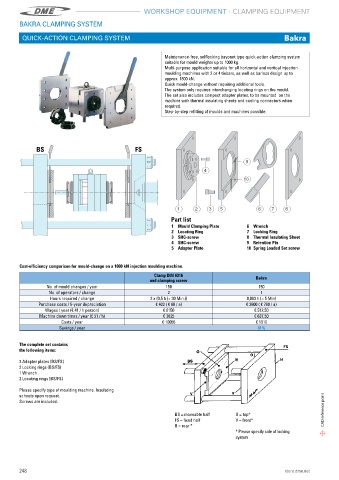

QUICK-ACTION CLAMPING SYSTEM Bakra

Maintenance-free, selflocking bayonet type quick-action clamping system

suitable for mould weights up to 1000 kg�

Multi-purpose application suitable for all horizontal and vertical injection

moulding machines with 2 or 4 tiebars, as well as barless design up to

approx� 1800 kN�

Quick mould-change without requiring additional tools�

The system only requires interchanging locating rings on the mould�

The set also includes compact adapter plates, to be mounted on the

machine with thermal insulating sheets and cooling connectors when

required�

Step-by-step refitting of moulds and machines possible�

BS FS

9

4

10

1 2 3 5 6 7 8

Part list

1 Mould Clamping Plate 6 Wrench

2 Locating Ring 7 Locking Ring

3 SHC-screw 8 Thermal Insulating Sheet

4 SHC-screw 9 Retention Pin

5 Adapter Plate 10 Spring Loaded Set screw

Cost-efficiency comparison for mould-change on a 1000 kN injection moulding machine.

Clamp DIN 6316 Bakra

and clamping screw

No� of mould changes / year 150 150

No� of operators / change 2 1

Hours required / change 2 x (0,5 h (= 30 Min�)) 0,083 h (= 5 Min)

Purchase costs / 5-year depreciation € 400 ( € 80 / a) € 3800 ( € 760 / a)

Wages / year (€ 41 / h person) € 6150 € 512,50

Machine down times / year (€ 51 / h) € 3825 € 637,50

Costs / year € 10055 € 1910

Savings / year 81%

The complete set contains

the following items:

2 Adapter plates (BS/FS)

2 Locking rings (BS/FS)

1 Wrench

2 Locating rings (BS/FS)

Please specify type of moulding machine. Insulating

scheets upon request.

Screws are included.

BS = moveable half O = top* CAD reference point

FS = fixed half V = front*

H = rear *

* Please specify side of locking

system

248 store.dme.net