Page 269 - DME Workshop Equipment Catalogue 2023 EN

P. 269

CONSUMABLES

WORKSHOP EQUIPMENT - CONSUMABLES

CASTING COMPOUNDS

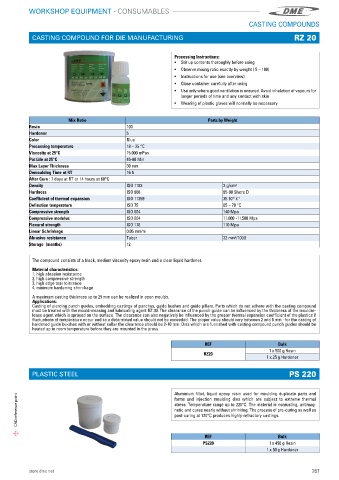

CASTING COMPOUND FOR DIE MANUFACTURING RZ 20

Processing Instructions:

• Stir up contents thoroughly before using

• Observe mixing ratio exactly by weight ( 5 – 100)

• Instructions for use (see overview)

• Close container carefully after using

• Use only where good ventilation is ensured� Avoid inhalation of vapours for

longer periods of time and any contact with skin

• Wearing of plastic gloves will normally be necessary

Mix Ratio Parts by Weight

Resin 100

Hardener 5

Color Blue

Processing temperature 18 – 25 °C

Viscosity at 25°C 15�000 mPas

Pot Life at 25°C 45-80 Min

Max Layer Thickness 30 mm

Demoulding Time at RT 16 h

After Cure : 7 days at RT or 14 hours at 60°C

Density ISO 1183 2 g/cm³

Hardness ISO 868 85-90 Shore D

Coefficient of thermal expansion ISO 11359 35 10 k -1

-6

Deflection temperature ISO 75 65 – 70 °C

Compressive strength ISO 604 140 Mpa

Compressive modulus ISO 604 11�000 -11�500 Mpa

Flexural strength ISO 178 110 Mpa

Linear Schrinkage 0�05 mm/m

Abrasive resistance Taber 22 mm³/100U

Storage (months) 12

The compound consists of a black, medium viscosity epoxy resin and a clear liquid hardener�

Material characteristics:

1� high abrasion resistance

2� high compressive strength

3� high edge tear tolerance

4� minimum hardening shrin-kage

A maximum casting thickness up to 25 mm can be realized in open moulds�

Applications:

Casting of piercing punch guides, embedding castings of punches, guide bushes and guide pillars� Parts which do not adhere with the casting compound

must be treated with the mouldreleasing and lubricating agent RZ 30� The clearance of the punch guide can be influenced by the thickness of the mouldre-

lease agent which is sprayed on the surface� The clearance can also negatively be influenced by the greater thermal expansion coefficient of the plastics if

fluctuations of temperature occur and so a determined value should not be exceeded� The proper value should vary between 2 and 6 mm - for the casting of

hardened guide bu-shes with or without collar the clearance should be 2-10 mm� Dies which are furnished with casting compound punch guides should be

heated up to room temperature before they are mounted in the press�

REF Bulk

1 x 500 g Resin

RZ20

1 x 25 g Hardener

PLASTIC STEEL PS 220

CAD reference point Aluminium filled, liquid epoxy resin used for moulding duplicate parts and

forms and injection moulding dies which are subject to extreme thermal

stress� Temperature range up to 220°C� The material is nonrusting, antimag-

netic and cures nearly without shrinking� The process of pre-curing as well as

post-curing at 120°C produces highly-refractory castings�

REF Bulk

PS220 1 x 450 g Resin

1 x 50 g Hardener

store.dme.net 267