Page 170 - DME Workshop Equipment Catalogue 2023 EN

P. 170

A

SURF

WORKSHOP EQUIPMENT - SURFACE FINISHING EQUIPMENT

CE FINISHING EQUIPMENT

POLISHING STONES

POLISHING STONES Info

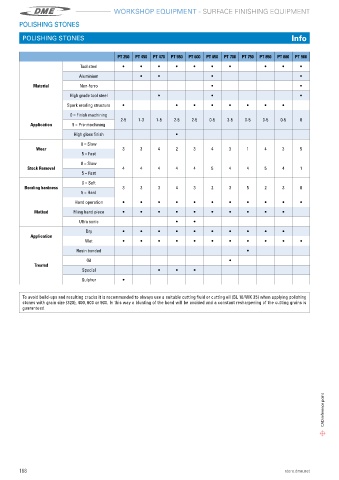

PT 250 PT 450 PT 470 PT 550 PT 600 PT 650 PT 700 PT 750 PT 850 PT 880 PT 900

Tool steel i i i i i i i i i i

Aluminium i i i i

Material Non-ferro i i

High grade tool steel i i i

Spark eroding structure i i i i i i i i

0 = Finish machining

2-5 1-3 1-5 2-5 2-5 0-5 3-5 0-5 0-5 0-5 0

Application 5 = Pre-machining

High gloss finish i

0 = Slow

Wear 3 3 4 2 3 4 3 1 4 3 5

5 = Fast

0 = Slow

Stock Removal 4 4 4 4 4 5 4 4 5 4 1

5 = Fast

0 = Soft

Bonding hardness 3 3 3 4 3 2 3 5 2 3 0

5 = Hard

Hand operation i i i i i i i i i i i

Method Filing hand piece i i i i i i i i i i

Ultra sonic i i

Dry i i i i i i i i i i

Application

Wet i i i i i i i i i i i

Resin bonded i

Oil i

Treated

Special i i i

Sulphur i

To avoid build-ups and resulting cracks it is recommended to always use a suitable cutting fluid or cutting oil (BL 10/WK 35) when applying polishing

stones with grain size (320), 400, 600 or 900� In this way a blunting of the bond will be avoided and a constant resharpening of the cutting grains is

guaranteed�

CAD reference point

168 store.dme.net